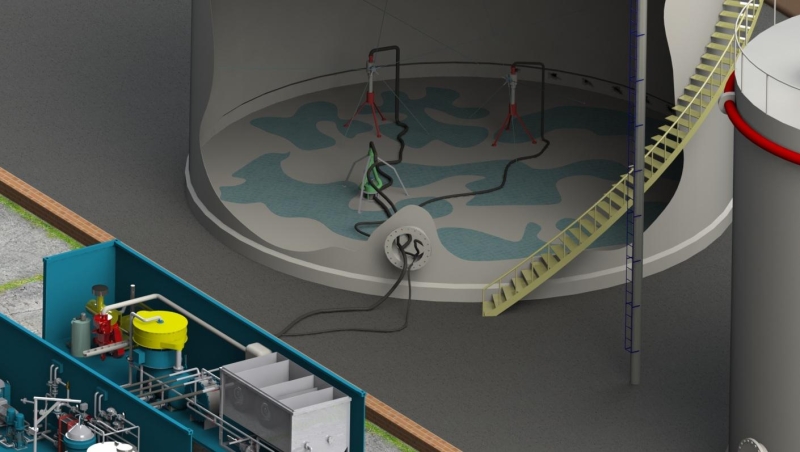

STAGE 5. TANK WASHING

After the total sediment removal the operator removes the washing gun and put inside the tank 2 or 3 washing heads.

The washing heads rotate at the angle of 360° in all directions and by water at the pressure of 200-290 psi perform washing- out of tank walls, cover and baffles.

The water supplied to washing heads is cleaned by centrifugal separator to be reused. In addition it undergoes re-heating by a separate plate heat exchanger installed in front of the separator.

Pumping of washing-out products is performed by pumpout heads with the following treatment inside the unit.