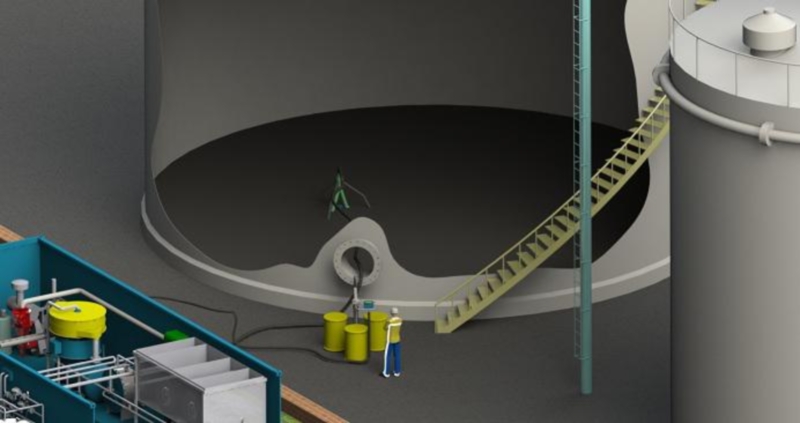

STAGE 3. SLUDGE EXTRACTION INSIDE THE RESERVOIR

After the sludge obstructing the tank cover has been washed out, operator installs the pumpout head inside the tank and continues washing-out.

|

| Round vibroscreen |

The pumpout head of the hydraulically actuated pump is covered with the protecting net and is mounted on the stand. The pump with the stand could be moved inside the tank manualy by one operator.

|

| Pumpout head |

The pumpout head itself and the stand are made of aluminium which provides full intrinsic (no sparks) safety of the instrument. The pumpout head and the protective sleeve are grounded to prevent a danger of fire and to increase the safety of the operational personal.

Washed out sludge gets into KERBER through the inlet round vibroscreen, which provides separation of large mechanical impurities with the size of more than 0,24 inch. Usually it is either domestic solid waste or an instrument or rubbish leftovers generated by building or repair work.

|

Initially the vibroscreen is of little importance because the protecting sieve of the pumpout head removes large impurities. But it performs the function of sediment vacuum cleaning at the end of the operation cycle.

While moving inside the tank, operator continuously shifts the pumping head simultaneously washing out the sludge in the direction of the pumpout head with the help of the water gun.