STAGE 2. TANK OPENING

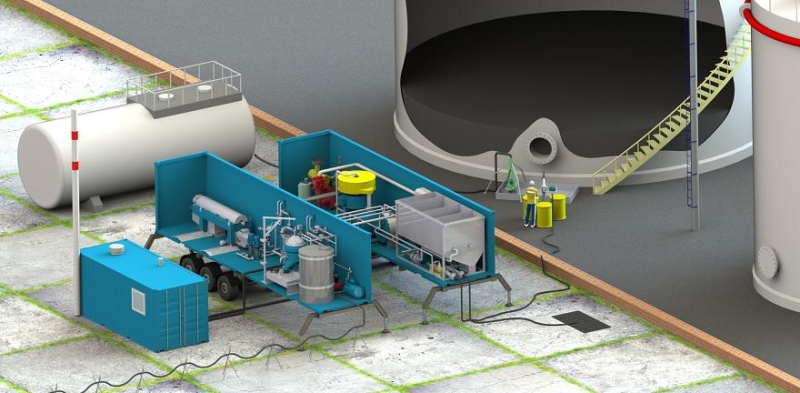

Operators check tightness of cleaning fluid supply sleeves and check functioning of all the systems before the tank opening.

Connected boiler station which provides heating of the cleaning agent to the temperature of 160-195° F is ready to supply the required hot water or steam.

Receiving tray for the oil sludge is placed under the assembly cover located at the container side. Power driven pumpout head with the help of which sludge and washing liquid pumpage is performed is placed into the receiving tray.

|

Very frequently the level of sediments in a tank is higher than any norm and because of this probability the receiving tray is placed outside of the tank.

Operators open up the cover and start sludge apparent volume washing-out process. Washing gun, which provides hot jet pressure of 200-290 psi is used for washing-out. Water gun fixation is provided by three aluminum casks filled with water and weighing more than 660 pounds when it is in the operation mode. The casks provide reliable fixation for the gun legs. Empty casks weigh no more than 16 pounds and with the diameter of 17,5 inch are easy to move in and out of the tank. The casks are filled automatically during the washing-out supply.